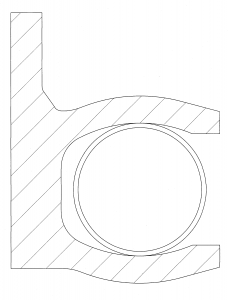

Helical Spring

Spring Energized Seal

Standard Part Numbering System

HS-SES-A-004-01-A1-M

HS-SES = Helical Spring Energized Seal

X = Seal Type

XXX = Standard Dash Size (See Chart Below)

XX = Standard Jacket Material (See Chart Below)

A1= Standard Spring Material (See Chart Below)

M = Military gland or I = Industrial Gland

Use the Guides Below to Construct your Part Number

Standard Dash Size

Standard Seal Materials

Detailed Gland Recommendations

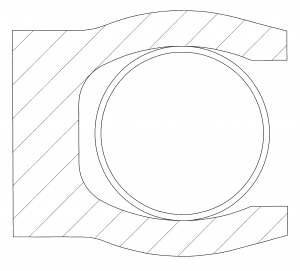

Type A: This is our basic Teflon spring energized seal configuration. Spring energized seals are spring loaded to maintain a positive seal and compensate for wear and misalignment. The helical spring energized seal is designed for static to slow dynamic motion. The average spring load (pounds per inch of seal circumference) is between 24-28 lbs depending on the seal cross section you are using. If not space constricted, we recommend using a larger cross section for better performance. System pressure assists the spring by pushing the sealing legs against the shaft and bore maintaining a tight seal. The standard type A seal design can withstand pressure up to 3000 PSI for industrial or military gland sizes. The type A seal configuration is designed to fit in the standard “G” gland width found on our detailed gland recommendations page and standard dash sizes page.

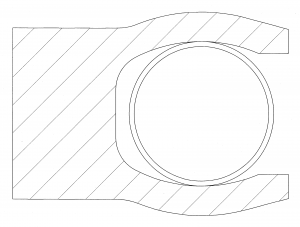

Type B: This is the same design as our basic Teflon spring energized seal configuration type A except, this design has an extended heel for additional pressure up to 5000 PSI. This type B seal configuration is designed to fit in the standard “G1” gland width found on our detailed gland recommendations page and standard dash size page.

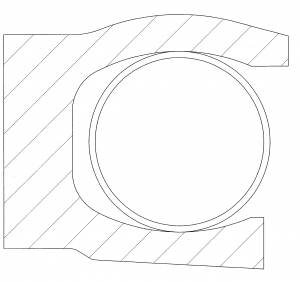

Type C: This is the same design as our basic Teflon spring energized seal configuration type A except, this design is for a rod seal configuration. The dynamic ID sealing leg has a scraper design to shave off any media that sticks to the shaft. The scraper leg design is at 90º angle from the shaft to keep debris from migrating between the shaft and sealing leg interface increasing seal performance. This type C seal configuration is designed to fit inside standard “G” gland width and also available with extended heel for the “G1” gland width.

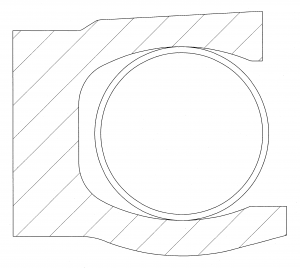

Type D: This seal design is identical to type C except this configuration is for a piston seal design.

Type E: Type E is recommended for any rotary application where a rotary shaft seal design will not fit because the radial cross section is too small. The flange will hold the spring energized seal in place as designed in lieu of the seal spinning with the shaft inside the gland.

Please contact sales for custom seal design and high pressure sealing applications