ROTARY SHAFT SEAL

Standard RSS Part Numbering System

RSS-A-001-M-06-A1

RSS = Rotary Shaft Seal – Lip Seal Designation

X = Seal Type

XXX = Standard Dash Size (See Chart Below)

X = Standard Width of Seal (See Chart Below – Standard Dash Size)

XX = Standard Seal Material (See Chart Below)

A1 = Standard O-Ring Material (See Chart Below – Standard Seal Material)

Use the Guides Below to Construct your Part Number

Standard Seal Materials

Standard Dash Sizes

Detailed Gland Reccomendations

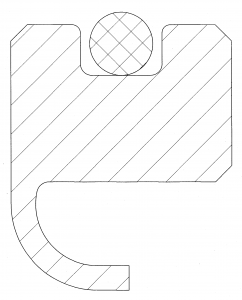

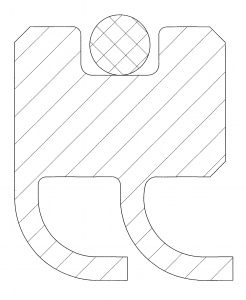

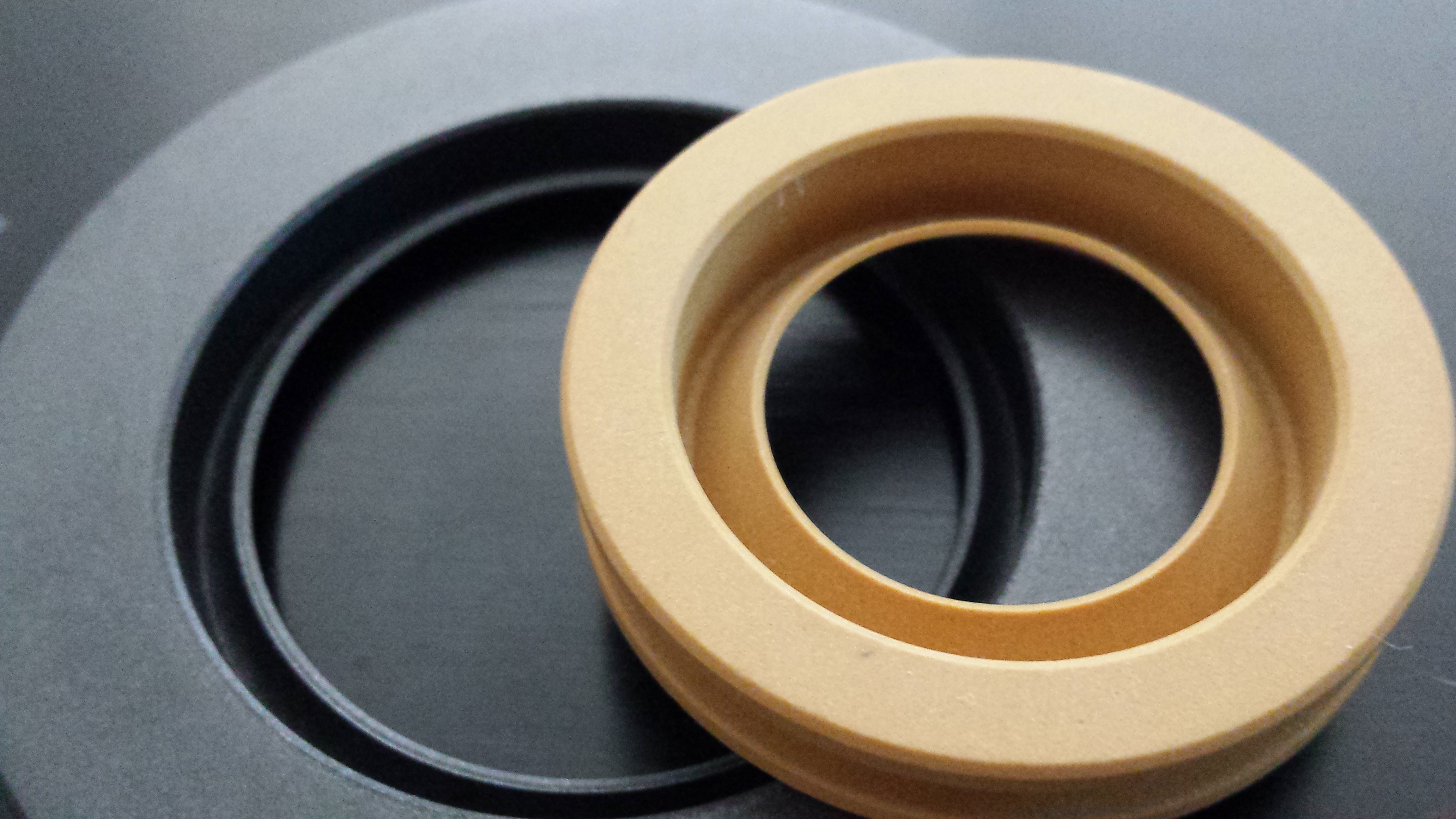

Type A: This design is the same as our basic Teflon metal case lip seal configuration type B. This seal is only to be used when axial space is limited. We can offer this design to fit in a shallow bore where type B will not fit. Please contact our sales department with your hardware configuration and let us layout a design to fit in your existing shallow bore.

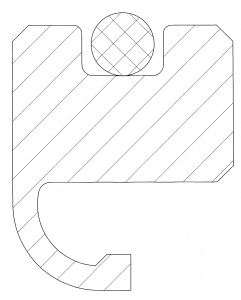

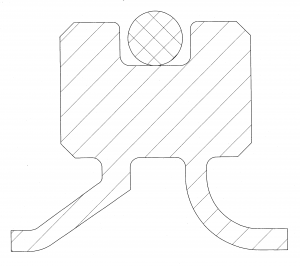

Type B: This is our basic Teflon metal case lip seal configuration. Teflon sealing elements can be used in lubricated and non-lubricating rotary applications. The type A seal is designed for shaft speeds up to 5000 ft/minute and pressure up to 100 PSID. The PTFE sealing element has a distributed load starting at the tip of the element and decreases towards the back of the seal when in the on shaft position. The distributed lip load minimizes wear on the sealing element extending seal life and maximizing performance. Please review the standard dash sizes and detailed hardware recommendations.

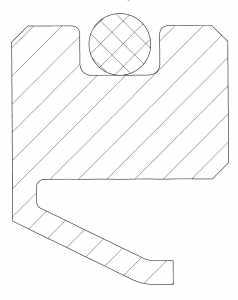

Type C: This seal type is typically used as a wiper, or dust excluder to keep atmospheric debris from migrating under the primary sealing lip from the backside of the seal. The angled sealing element has a light load compared to type A which can be used in excess of 7500/ft per minute. This seal is not designed for pressure over 20 PSID. This seal has been successful in high speed steam applications and an excellent environmental seal.

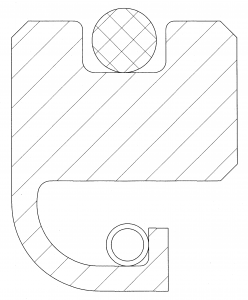

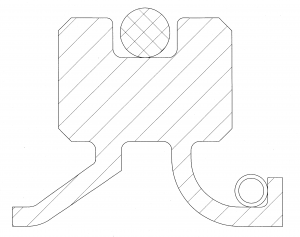

Type D: This seal type is the same as type A except, the sealing element is designed with an extra high load at the tip of the sealing element using a garter spring. The extra high tip load adds support against abrasive media keeping particles from migrating between the sealing element and shaft interface. This garter spring design is also great for bore to shaft misalignment or when runout is a problem.

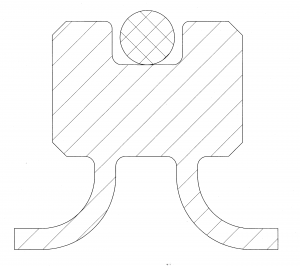

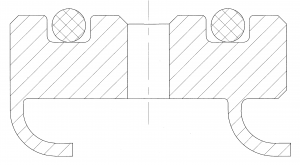

Type E: This is our double lip Teflon metal case lip seal configuration. The dual Teflon sealing elements can be used in lubricated and non-lubricating rotary applications. The type E seal is designed for shaft speeds up to 4000 ft/minute and pressure up to 500 PSID. The secondary PTFE sealing element acts as a backup supporting the primary element. This design is excellent for hydraulic motors, pumps, and any other high pressure rotary application. Please review the standard dash sizes and detailed hardware recommendations.

Type F: Type F is identical to out type B configuration, except this design has incorporated a wiper design (see type C) to act as a dual sealing system. The primary sealing element can function as designed while the wiper element keeps atmospheric debris from migrating under the primary sealing element from the back side. Please review the standard dash sizes and detailed hardware recommendations.

Type G: Type G is identical to out type E configuration, except this design has incorporated a wiper design (see type C) to act as a dual sealing system. The primary sealing element can function as designed while the wiper element keeps atmospheric debris from migrating under the primary sealing element from the back side. The type G seal is designed for shaft speeds up to 4000 ft/minute and pressure up to 500 PSID Please review the standard dash sizes and detailed hardware recommendations.

Type H: This design is similar to is our basic Teflon metal case lip seal configuration type B except, this design incorporates a hydro dynamic knife cut in the sealing element which pumps the media away from the seal. This design is NOT to be used in un-lubricated environments. This seal is designed for shaft speeds up to 6000 ft/minute and pressure up to 5 PSID. The standard design is for shafts rotating in the clockwise direction viewed from the heel side of the seal Please contact our sales department for counter clockwise seal designs. Please review the standard dash sizes and detailed hardware recommendations.

Type I: This design is similar to is our basic Teflon metal case lip seal configuration type G except, this design incorporates a hydro dynamic knife cut in the primary sealing element which pumps the media away from the seal. This design is NOT to be used in un-lubricated environments. This seal is designed for shaft speeds up to 5000 ft/minute and pressure up to 250 PSID. The standard design is for shafts rotating in the clockwise direction viewed from the heel side of the seal. Please contact our sales department for counter clockwise seal designs. Please review the standard dash sizes and detailed hardware recommendations. Typical applications include vacuum pumps, air compressors, and refrigeration units.

Please contact sales for custom seal design and high pressure sealing applications